A multifaceted crisis is rapidly brewing within the United States’ digital infrastructure, as a confluence of powerful forces has created a critical shortage of fiber-optic cable that now casts a shadow over the nation’s ambitious broadband expansion goals. This situation, described by industry insiders as a “perfect storm,” is not a simple supply-and-demand imbalance but a complex web of unprecedented technological demand, severe manufacturing bottlenecks, restrictive government policies, and escalating geopolitical tensions. This scarcity directly threatens the viability of federally funded initiatives like the landmark Broadband Equity Access and Deployment (BEAD) program and jeopardizes the extensive network build-out plans of private telecommunication giants. The consensus viewpoint is clear: without a resolution, the goal of achieving universal, high-speed internet access for every American faces a significant and potentially insurmountable obstacle, delaying a crucial step in the country’s technological and economic future.

Drivers of the Shortage: A Two-Front Problem

The Demand Side: An AI-Fueled Fire

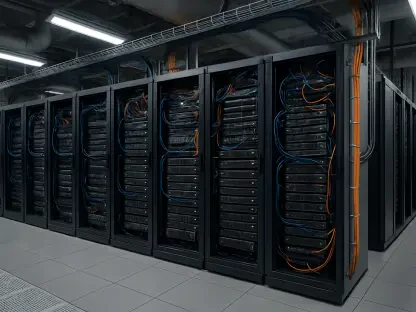

The primary catalyst igniting this crisis is the explosive and largely unforeseen demand stemming from the technology sector’s “hyperscale gold rush” into artificial intelligence. The rapid development and training of sophisticated large language models (LLMs) necessitate the construction of massive, sprawling data centers that are incredibly fiber-intensive, creating a voracious new appetite for connectivity that has caught the supply chain entirely off guard. This surge is so profound that industry figures, such as Mike Riddle, president of Incab America, have issued stark warnings that these data centers are effectively “sucking up all the fiber production capacity.” This sentiment is strongly supported by financial analysts at UBS, who have observed that despite broader economic debates, growth forecasts for AI-related spending have not only remained robust but have actually seen upward revisions. This indicates that the intense demand for fiber is not a fleeting market spike but a sustained, structural trend that will continue to strain resources for the foreseeable future.

This demand shock has been dramatically amplified by a fundamental technological shift occurring within the architecture of these new AI-focused data centers. The industry-wide transition from traditional central processing units (CPUs) to vastly more powerful and parallel-processing-capable graphics processing units (GPUs) has single-handedly caused a tenfold increase in the fiber requirements needed both within individual facilities and for the interconnects between them. This is not merely an incremental increase; it represents a paradigm shift in how data infrastructure is designed and built. The immense bandwidth required to network thousands of GPUs for training a single AI model has structurally embedded an unprecedented level of fiber demand into the core of the AI industry’s growth trajectory. As a result, the pressure on the global fiber supply chain is now intrinsically linked to the expansion of artificial intelligence, ensuring that this heightened demand will persist and likely grow as AI technology continues to advance and proliferate across industries.

The Supply Side: A Strained Production Chain

Overwhelmed by this tsunami of new orders, the manufacturing and supply side of the fiber-optic industry is experiencing a significant bottleneck, leading to dramatically extended lead times for essential materials. According to an anonymous industry source, the standard procurement time for fiber-optic cable, which typically hovers between eight and twelve weeks, has ballooned to a full year—a level of delay not witnessed since the height of the dot-com bubble in 2000. This immense pressure is straining the capacity of the nation’s foremost glass manufacturers, including industry leaders like Corning, Lightera, and Prysmian, as they struggle to scale up production to meet the relentless pace of demand. The situation has grown so severe that, as of last August, observations from Riddle indicated that one major manufacturer had already completely sold out its entire fiber inventory through the year 2026, leaving many network builders scrambling for alternative sources and facing uncertain project timelines.

The severity of the production crunch is further underscored by the strategic moves being made by the industry’s largest players. By October, rumors began to circulate that Corning, the world’s leading producer of optical fiber, had ceased selling its raw glass to other cable manufacturers in a bid to prioritize its own finished cable production. While Corning’s CEO, Wendell Weeks, did not directly confirm this specific action, he publicly acknowledged that the profound imbalance between soaring demand and constrained supply had placed the company in a “quite tight” situation. This predicament has necessitated difficult strategic discussions with major customers about their future manufacturing profiles and supply allocations. This development highlights a critical reality: even the most dominant and well-resourced manufacturers are being forced to make challenging decisions, signaling that the supply-side constraints are deep, systemic, and unlikely to be resolved without significant new investment in production capacity.

Exacerbating the Crisis: Policy and Geopolitics

Domestic Roadblocks to Deployment

Compounding the severe supply and demand crisis are significant hurdles created by domestic government policies that, while well-intentioned, are creating considerable frustration within the industry. The Build America, Buy America (BABA) Act, signed into law in late 2021, mandates that any project receiving federal financial assistance must utilize iron, steel, manufactured products, and construction materials produced within the United States. These provisions have a direct and challenging impact on the $42.45 billion BEAD program, which is specifically designed to extend high-speed network coverage to underserved and hard-to-reach communities across the country. Key stakeholders have voiced strong fears that the strict domestic sourcing requirements will make it practically impossible to acquire the necessary network components in a timely and cost-effective manner, thereby jeopardizing BEAD’s ultimate goal of providing reliable internet access to “every American” by the 2030 deadline. This has sparked active lobbying efforts aimed at securing a relaxation of the BABA rules to prevent them from becoming an insurmountable roadblock to progress.

Further complicating the procurement landscape, tariff restrictions on foreign goods, which were put in place by the previous administration, continue to make sourcing essential components from overseas both more challenging and more expensive. These tariffs act as an additional layer of friction on an already strained supply chain, limiting the options available to network builders and driving up the overall cost of deployment. When combined with the stringent BABA requirements, these policies create a restrictive environment that inadvertently works against the national goal of rapid and widespread broadband expansion. While the objective of bolstering domestic manufacturing is a laudable one, the current reality is that these protectionist measures are constricting the flow of critical materials at a time when they are needed most, creating a policy-induced bottleneck that exacerbates the existing market-driven shortages and threatens to slow down critical infrastructure projects nationwide.

The Global Squeeze on Raw Materials

The final element completing this perfect storm is a growing and significant concern over international access to essential raw materials, specifically the element germanium. This material is a critical and irreplaceable component in the manufacturing of the specialized glass used in high-performance fiber-optic cables. Historically, the global supply chain has been heavily reliant on a single source, with approximately 80% of the world’s germanium being sourced from China. However, in a move widely perceived as a retaliatory measure against U.S. restrictions on the export of advanced semiconductor technology, China has recently begun to restrict its own export of germanium. This action injects a considerable degree of geopolitical risk directly into the fiber supply chain, threatening to choke off a vital raw material at its very source and further destabilize an already strained and volatile market.

This deliberate restriction on a critical resource introduces a dangerous new dimension to the ongoing supply crisis, transforming a manufacturing and logistics challenge into a matter of international strategy and diplomacy. By leveraging its dominance in the germanium market, China has the ability to exert significant pressure on Western technology sectors, potentially disrupting production schedules and driving up costs for fiber-optic cable manufacturers globally. This move threatens to create an even more acute shortage, as companies may be forced to compete for a dwindling supply of essential raw materials or invest heavily in developing alternative, less-efficient sources. The weaponization of raw material exports destabilizes long-term planning for network infrastructure projects and underscores the vulnerability of relying on single-source, geopolitically sensitive supply chains for components that are fundamental to national security and economic development.

The Ripple Effect: Consequences for America’s Digital Future

The overarching implications of this crisis proved to be far-reaching and deeply consequential. The primary and most immediate threat was to the nation’s ambitious broadband targets, as a palpable sense of skepticism permeated the industry. Even leaders of telecommunications giants, such as AT&T CEO John Stankey, voiced doubts about whether publicly announced deployment goals could realistically be met in the face of such severe permitting hurdles and supply chain disruptions. The BEAD program, specifically engineered to connect the country’s most isolated and unserved communities, was left particularly vulnerable to these delays. Beyond the failure to meet national connectivity goals, the crisis predictably drove up the costs of privately funded projects, and these increased expenses were ultimately passed on to consumers in the form of higher prices. For major equipment vendors, the situation presented a complex challenge, while for manufacturers like Corning, the tight market created a double-edged sword: production was strained, yet the scarcity also led to favorable market conditions with an improving product mix and higher profit margins, a trend that looked set to persist for the foreseeable future.