Industrial leaders are confronting a critical and increasingly urgent dilemma as the drive to innovate with technologies like artificial intelligence, autonomous vehicles, and widespread sensor deployment demands unprecedented levels of network connectivity. This very connectivity, however, opens the door to sophisticated cyber threats that can bring entire operations to a grinding halt, costing millions in lost revenue and reputational damage. For decades, organizations have been forced into a precarious balancing act, often compelled to choose between maintaining seamless production uptime and implementing the robust security measures necessary to protect their critical assets. This historic trade-off is no longer acceptable in today’s high-stakes environment, where operational efficiency and digital resilience are intertwined. The central question now is whether it is truly possible for an enterprise to achieve both flawless operational reliability and ironclad security simultaneously, without compromising either essential objective.

The Modern Industrial DilemmInnovation vs. Risk

The New Operational Reality

The contemporary industrial landscape is undergoing a transformation so dramatic that it is fundamentally reshaping entire sectors. Technologies that were once confined to research labs, such as AI-vision systems that perform real-time quality control on assembly lines, autonomous guided vehicles (AGVs) that autonomously navigate complex warehouse floors, and the massive data streams generated by the Industrial Internet of Things (IIoT), are no longer futuristic concepts but daily operational realities. This profound evolution requires a networking infrastructure that is fundamentally different from what came before, one that is not just incrementally better but vastly more reliable, faster, and more secure. The demand is for a network that can handle the deterministic, low-latency communication required for machine control while simultaneously supporting the high-throughput data backhaul needed for advanced analytics, creating a complex set of requirements that legacy systems were never designed to meet.

This technological leap toward a data-driven industrial model places immense pressure on the underlying digital infrastructure, where the consequences of failure are immediate and severe. The sheer volume and velocity of data generated by modern sensors and autonomous systems are essential for unlocking new efficiencies through predictive maintenance, process optimization, and the continuous training of AI algorithms. For this value to be realized, data must flow uninterrupted and with minimal delay. Traditional enterprise networks often become bottlenecks in these demanding environments, stifling innovation and limiting the potential of these advanced technologies. The new imperative is to build a cohesive digital fabric capable of supporting both sensitive operational control signals and massive data flows concurrently, ensuring that a dropped packet does not result in a physical collision or a critical flaw in production.

The High Cost of IT/OT Convergence

Fueling this industrial revolution is the accelerating convergence of Information Technology (IT) and Operational Technology (OT), a trend that promises unparalleled efficiency but also introduces profound risks. Historically, OT systems that manage physical processes were protected by an “air gap,” a physical isolation from IT networks and the outside world. To harness the power of data, however, this gap has been systematically bridged, allowing for remote monitoring, control, and analytics. While this integration is vital for competitiveness, it has also erased the traditional security perimeter, exposing sensitive industrial controls to the same cyber threats that plague the IT world. Consequently, a single cyber breach is no longer just a data security incident; it can trigger a catastrophic physical event, leading to production shutdowns, equipment damage, environmental hazards, and even threats to human safety. The financial and operational stakes have never been higher.

Compounding this technical challenge is a growing wave of regulatory and compliance pressures from governmental bodies and industry standards organizations. Frameworks such as the CISA’s Zero Trust security model and directives like the EU’s NIS2 are no longer abstract guidelines but stringent mandates that require organizations to demonstrate comprehensive network visibility, granular segmentation, and strict access controls. Compliance is not optional, and the penalties for failure can be severe, adding another layer of complexity for industrial leaders. This regulatory landscape intensifies the core conflict, as traditional security tools and practices are often incompatible with sensitive OT environments, where even a simple network scan can cause a critical system to fail. This forces organizations into a difficult position, caught between the need to secure their operations and the absolute requirement to keep them running without interruption.

A Two-Pronged Solution for a Unified Goal

Fortifying Uptime with Next-Generation Wireless

Addressing the non-negotiable need for constant uptime in mobile, mission-critical industrial applications requires a fundamentally new class of wireless technology. Traditional Wi-Fi, even in its latest iterations, is engineered for best-effort connectivity, which is entirely inadequate for use cases like remotely operated port cranes or fleets of AGVs, where flawless mobility and near-instantaneous response times are paramount. These applications cannot tolerate the packet loss, high latency, or connection drops that frequently occur during handoffs between access points in a standard wireless environment. To fill this critical gap, specialized solutions like Cisco’s Ultra-Reliable Wireless Backhaul (URWB) were engineered from the ground up, specifically designed to deliver latency of less than 10 milliseconds and provide true seamless mobility, ensuring that real-time control and data transmission are never compromised, even for assets moving at high speed.

The technological innovation that enables this level of reliability is centered on a “make-before-break” handoff mechanism, which stands in stark contrast to the “break-before-make” approach used by conventional wireless systems. For a moving asset, this means a new, stable connection to the next access point is established and validated before the previous one is disconnected, guaranteeing a truly seamless transition with zero packet loss and no disruption to the application. This core capability is further fortified with advanced features designed for harsh industrial environments, including a sub-500ms failover time and a technology known as Multipath Operations. This latter feature enhances data integrity by intelligently replicating and sending critical data packets across up to eight independent wireless paths simultaneously, ensuring that messages are delivered successfully even if some paths experience significant radio frequency interference or temporary obstruction.

The Practical Path to Unshakeable Connectivity

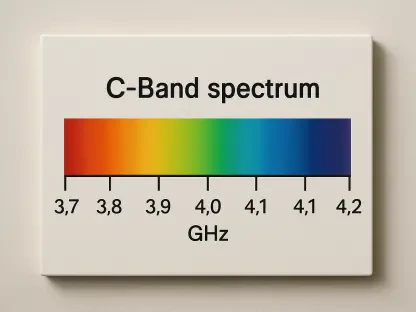

A significant strategic advantage of advanced wireless systems like URWB is their ability to deliver performance and reliability comparable to that of private 5G networks while operating on globally available, unlicensed spectrum. This allows organizations to sidestep the formidable costs, complex regulatory hurdles, and lengthy deployment timelines associated with acquiring and managing licensed cellular spectrum. By leveraging unlicensed bands, industrial enterprises can deploy carrier-grade wireless connectivity in a more agile and cost-effective manner, democratizing access to the high-performance networking required for next-generation automation and control. This pragmatic approach removes a major barrier to innovation, making it feasible for a wider range of organizations to modernize their operations without embarking on a multi-million dollar infrastructure project centered on licensed spectrum acquisition.

Furthermore, these next-generation wireless solutions are designed for practical integration into existing enterprise network environments, which dramatically simplifies deployment and lowers the total cost of ownership. URWB, for instance, can operate concurrently with standard Wi-Fi protocols—including Wi-Fi 7, 6E, and 6—on the same hardware platforms and can be managed using the same networking tools and dashboards that IT teams already use. This unified approach eliminates the need for separate, siloed networks for different types of devices or environments, such as one for IT and another for OT. By leveraging existing infrastructure and skill sets, organizations can minimize the need for specialized training, reduce infrastructure sprawl, and accelerate the adoption of a more reliable wireless fabric across their entire operational footprint, from indoor factory floors to expansive outdoor yards.

Embedding Security with AI-Powered Intelligence

On the security front, implementing a Zero Trust architecture through network segmentation in OT environments has been a historically difficult, if not impossible, endeavor. This challenge is rooted in four significant and persistent barriers: severely limited visibility into legacy industrial assets and their proprietary protocols; physical and architectural infrastructure constraints that make adding new security hardware difficult; the absolute requirement for zero downtime in production systems, which makes any network change risky; and a chronic shortage of personnel with dual expertise in both IT security and OT industrial processes. To overcome these deep-seated problems, an innovative approach has emerged that embeds security capabilities directly into the network infrastructure itself, thereby eliminating the need to introduce external security appliances that add complexity, cost, and potential points of failure into sensitive operational environments.

This modern approach to OT security is exemplified by solutions like Cisco Cyber Vision, which turns the network itself into a comprehensive sensor. By embedding security-focused software directly into industrial switches, routers, and wireless access points, the system can passively analyze all network traffic without disrupting real-time industrial processes. This method allows it to perform deep packet inspection on a wide range of proprietary OT protocols, enabling it to automatically discover and create a detailed inventory of every connected device, from modern robots to decades-old PLCs. This foundational step of achieving complete asset visibility is the critical prerequisite for any effective security strategy, providing a clear and accurate picture of what is on the network and how it communicates before any security policies are even considered.

How AI-Powered Segmentation Works

The core of this advanced security framework is a sophisticated, AI-powered segmentation engine that moves far beyond simple device discovery. After identifying every asset, the engine passively analyzes all communication patterns over time to understand the operational context and normal behaviors of each device. It learns, for example, that a specific controller on a bottling line should only ever communicate with a particular set of sensors and human-machine interfaces (HMIs) and should never attempt to reach the internet. Based on this deep analysis, the AI automatically organizes thousands of disparate OT assets into logical security zones that accurately reflect their function within the industrial process. This transforms a painstaking manual process that could previously take a team of experts months or even years of work into an automated one that delivers validated results in a matter of weeks.

Once these AI-generated groupings have been reviewed and validated by the OT teams who understand the industrial process best, the information is seamlessly synchronized in real time with security enforcement points across the network, such as Cisco Secure Firewalls and the Cisco Identity Services Engine (ISE). This crucial step bridges the persistent and often problematic gap between IT and OT teams. It allows IT security personnel to apply consistent, granular security policies—such as “Allow communication only within the ‘Robotic Welding Cell’ zone”—without needing to understand the intricate details of industrial protocols like Modbus or PROFINET. This protects production uptime while enabling the rapid and effective implementation of a robust Zero Trust architecture, ensuring that industrial operations can be both highly efficient and securely segmented.

The Unifying Power of an Integrated Architecture

Ultimately, the ability for an industrial enterprise to successfully balance the competing demands of uptime and security resided not in deploying individual, best-of-breed point products, but in adopting an integrated platform approach. By combining advanced wireless technologies for reliability with deeply embedded security capabilities, organizations created a unified architecture from a single vendor that spanned their entire operational footprint. This strategy decisively eliminated the complexity, integration costs, and management overhead associated with managing disparate systems for different environments, such as indoor manufacturing floors, outdoor logistics yards, and corporate campus networks. The resulting business impact was direct and substantial: it led to lower overall infrastructure costs, radically simplified network management, and, most importantly, provided the operational agility required for industries to innovate and scale their operations with confidence.

This cohesive strategy marked a pivotal turning point, allowing industrial leaders to finally move beyond the restrictive, binary choice between reliability and security. The integrated platform approach demonstrated that these two objectives were not mutually exclusive but were, in fact, two sides of the same coin, best addressed through a unified architectural vision. By building their modernization efforts on a foundation that inherently combined carrier-grade reliability with AI-powered, embedded security, organizations found they had unlocked unprecedented resilience and agility. They were able to deploy the next wave of industrial innovation—from autonomous systems to AI-driven automation—knowing their infrastructure had been transformed from a potential barrier into their most powerful and dependable enabler.