The Hannover Messe event has illuminated the transformative power of industrial artificial intelligence (AI), demonstrating its pivotal role in shaping the future of manufacturing technologies. IoT Analytics’ extensive report encapsulates these advancements, highlighting the infusion of industrial AI across the entire technology stack, revolutionizing edge solutions and cloud-based software. Generative AI’s widespread integration into industrial platforms complements the nascent rise of agentic AI, sparking new conversations and evoking excitement across the sector. Industry experts have noted how edge technologies are undergoing a period of significant innovation and transformation, resulting in enhanced data processing capabilities and improving operational efficiencies. Amid these advancements, there’s an increasing demand for DataOps platforms to handle the influx of data across manufacturing processes. These trends suggest a future where industrial AI is not merely an ancillary component but a cornerstone of manufacturing innovation, driving efficiency, precision, and creative solutions.

The Role of Advanced Technologies in Manufacturing

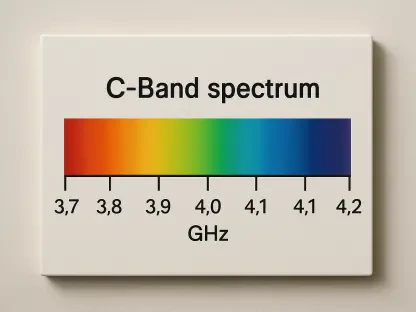

Manufacturing is undergoing a profound transformation, driven by the integration of cutting-edge technologies such as digital twins, sensor-centric predictive maintenance, and private 5G connectivity. Digital twin technology, once perceived as mere replicas, has evolved into dynamic, real-time copilots that elevate operational efficiency by offering real-time insights and enabling proactive decision-making. The shift toward sensor-centric predictive maintenance marks a pivotal change, focusing on previously neglected asset categories and promising significant cost savings by predicting mechanical failures before they occur. These advancements demonstrate how factories can operate more efficiently, reducing downtime and improving product quality. Moreover, the rise of private 5G connectivity is paving the way for more robust integration solutions, ensuring seamless communication across various manufacturing processes. By facilitating faster and more reliable data exchange, private 5G networks enable companies to leverage AI to its fullest potential, further ingrain technology into the fabric of manufacturing operations.

These technological strides are not only reshaping how manufacturing processes are managed but also redefine the competitive landscape of the industry. Companies are compelled to adopt these innovations to remain relevant and competitive. The focus on sensor-centric maintenance and 5G connectivity highlights a trend toward smarter, more interconnected factory floors. This transformation promotes a more cohesive approach where data flows effortlessly between systems, facilitating timely decision-making and fostering innovation. As a result, businesses can harness the full spectrum of AI technologies to enhance productivity and operational efficiencies. The evolution in manufacturing processes signifies a shift towards a more sustainable and responsive industrial ecosystem, positioning companies to better navigate the complexities of current and future market demands.

Unlocking AI’s Full Potential in the Industry

AI’s potential in transforming manufacturing is profound, with emerging trends indicating even deeper integration into industry-specific solutions. AI-powered sustainability strategies are increasingly coming to the fore, offering manufacturers tools to optimize energy use, reduce waste, and streamline operations with minimal environmental impact. Cognitive advancements in robotics have further augmented AI’s capabilities, suggesting a future where AI-driven robots are not only central to production lines but also capable of undertaking complex tasks with a high degree of accuracy. These robotics advancements enable manufacturers to maintain a competitive edge while addressing labor shortages and the demand for high-precision tasks.

Industry leaders have emphasized the importance of a collaborative ecosystem to unlock AI’s full potential, advocating for collaboration among AI vendors, manufacturers, and technology developers. This teamwork is critical for creating bespoke AI solutions that address the unique challenges and opportunities within the manufacturing sector. The report showcased numerous vendor examples highlighting how partnerships across the ecosystem are fundamental to the development and implementation of formidable AI solutions. Furthermore, CEOs and analysts predict industry-specific solutions will be pivotal in harnessing AI’s full capabilities.

The insights from the Hannover Messe report suggest that industrial AI, alongside edge-native architectures and DataOps platforms, will drive the manufacturing sector’s next wave of innovation. As these technologies continue to mature, businesses must remain agile, embracing these advancements not only for operational improvement but as a strategy for growth and long-term sustainability. The effective integration of AI into manufacturing is not just altering present capabilities but is setting the stage for a future where innovation is no longer confined to traditional boundaries.

Future Considerations in AI Integration

The Hannover Messe event showcased how industrial artificial intelligence (AI) is reshaping manufacturing, underlining its key role in future technologies. IoT Analytics’ comprehensive report outlines these breakthroughs, emphasizing how industrial AI is being integrated throughout the technology stack, transforming both edge solutions and cloud-based systems. This includes the widespread use of generative AI in industrial platforms, boosting the early adoption of agentic AI. This has sparked stimulating discussions and widespread enthusiasm within the industrial sector. Experts have observed substantial innovation and change in edge technologies, leading to better data processing and improved operational efficiency. Amid these developments, there is a growing need for DataOps platforms to manage the expanding flow of data in manufacturing processes. Together, these trends point toward a future where industrial AI is integral, serving as a foundational element of manufacturing progress, enhancing efficiency, precision, and fostering innovative solutions.