A New Era in Automotive Manufacturing

The unveiling of Hyundai’s HMG Metaplant America in Georgia represents a significant milestone in the evolution of automotive manufacturing in the United States. Hyundai’s investment trajectory in the U.S. market has been impressive, starting from initial operations decades ago to becoming a key player in the automotive sector. This latest $7.6 billion factory underscores Hyundai’s dedication to technological advancement and its strategic move toward electric and hybrid vehicle production.

Various experts suggest that the new facility is poised to revolutionize automotive manufacturing with its advanced technologies. The emerging innovations, including AI, autonomous robotics, and private 5G connectivity, position Hyundai at the forefront of Industry 4.0. The following sections delve into the technological advancements within this groundbreaking factory, exploring insights and perspectives from multiple industry sources.

Technological Advancements That Define the Factory

Integration of Advanced AI Systems

Industry leaders recognize the transformative potential of AI systems in streamlining assembly lines. The AI-driven processes at HMG Metaplant America enhance efficiency by aligning parts accurately and conducting final inspections meticulously. Reported data indicates significant gains in efficiency and substantial error reduction, though some experts express concerns about AI reliability and safety protocols.

Some analysts argue that while AI holds great promise, comprehensive safety measures are crucial to mitigate operational risks. The ongoing refinement of AI technologies aims to address these challenges, ensuring both reliability and safety.

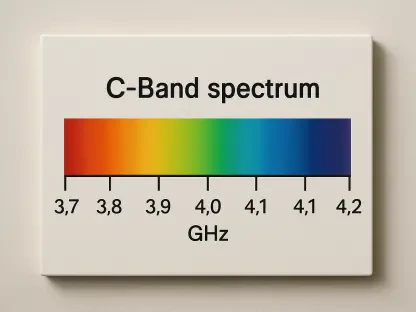

Autonomous Robotics and 5G Connectivity

Autonomous robots play a pivotal role at Hyundai’s new facility by managing heavy parts and performing various tasks with high precision. Experts emphasize the importance of private 5G connectivity in optimizing robotic operations, as it ensures seamless communication and real-time data exchange. The presence of this connectivity is considered a game-changer in industrial automation.

Industry observers believe that the continuous integration of 5G technology will further enhance factory operations, creating more interconnected and efficient manufacturing ecosystems. These advancements are likely to shape the future landscape of industrial automation and connectivity substantially.

Impact of Vertical Integration with New Steel Mill

The strategic placement of a new steel mill in Louisiana is viewed as a critical factor in Hyundai’s vertical integration strategy. By ensuring a steady supply of automotive steel plates, the new mill streamlines production processes, reduces costs, and maintains high-quality standards. Industry pundits highlight the benefits of such large-scale integration, noting that it optimizes production cycles and minimizes reliance on external suppliers.

However, some experts advise caution regarding the logistical and operational challenges involved in large-scale vertical integration. While the benefits are clear, effective management and coordination are essential to maximize the advantages fully.

Unprecedented Levels of Automation

HMG Metaplant America’s automation distinguishes it as a leader in modern manufacturing. Specific automated processes, including AI-driven systems for detecting imperfections, set this factory apart. Emerging trends in manufacturing automation suggest an increase in efficiency and precision, reducing human error and boosting overall productivity.

Contrary to common assumptions, automation does not necessarily lead to widespread job losses. Many experts argue that it reallocates the workforce toward more skilled roles, fostering growth and innovation within the industry. The ongoing dialogue about the workforce impact highlights the need for continuous adaptation and training.

Collaborations and Economic Impact

Hyundai’s partnerships with LG Energy Solution, SK On, and the local Georgia workforce mark significant collaborative efforts. These alliances play a vital role in driving local economic growth, creating new job opportunities, and fostering community investments. Comparatively, Georgia’s strategic economic initiatives stand out as potent catalysts for statewide development.

Economic analysts point to the favorable outcomes of such collaborations, emphasizing the long-term benefits for local economies. As similar strategies are employed by other states, the positive impact on job creation and local investments becomes more evident.

Strategic Insights and Best Practices

Hyundai’s investment in HMG Metaplant America exemplifies a blueprint for technological innovation in manufacturing. Key elements, including AI integration, robotics, and 5G connectivity, showcase best practices for industry players seeking to innovate. For manufacturers aiming to integrate advanced technologies, Hyundai’s approach provides valuable insights.

Recommendations include adopting comprehensive AI systems, embracing vertical integration, and ensuring robust connectivity infrastructure. Successful integration of these technologies requires a strategic vision, continuous adaptation, and commitment to excellence.

The Future of Manufacturing: What’s Next?

The implications of Hyundai’s investment extend beyond the automotive industry, shaping the future of mobility in America. The establishment of HMG Metaplant America sets a new standard for manufacturing excellence, driven by technological innovation and strategic foresight. Looking ahead, the next waves of innovation will likely introduce further advancements, potentially transforming manufacturing practices globally.

Embracing these changes, manufacturers are encouraged to adopt advanced technologies and collaborative approaches to stay competitive. The journey toward a smarter, more efficient manufacturing landscape continues, promising significant advancements and opportunities.