I’m thrilled to sit down with Vladislav Zaimov, a seasoned telecommunications specialist with a deep understanding of enterprise solutions and network risk management. With years of experience in the field, Vladislav has witnessed firsthand the transformative power of private 5G networks in industrial settings. Today, we’ll dive into how these networks are revolutionizing Industry 4.0, driving rapid returns on investment, enhancing AI integration, and improving safety, security, and sustainability across various sectors. Let’s explore the incredible potential of this technology and what it means for the future of industrial operations.

How would you describe private 5G networks, and what sets them apart from public 5G when it comes to industrial applications?

Private 5G networks are dedicated, on-site wireless networks tailored specifically for a single organization or facility, unlike public 5G, which is shared across multiple users and managed by telecom carriers. In industrial settings, private 5G offers greater control over data, security, and performance. These networks are built to handle the unique demands of factories, mines, or logistics hubs—think ultra-low latency for real-time automation or high bandwidth for massive sensor data. Public 5G, while powerful, can’t always guarantee the same level of customization or reliability in harsh, complex environments, making private 5G a game-changer for Industry 4.0.

What’s driving industrial companies to adopt private 5G and edge computing over other connectivity solutions?

The push toward private 5G and edge computing comes down to speed, control, and efficiency. Industries need connectivity that can support real-time decision-making, especially for applications like robotics or predictive maintenance. Edge computing, paired with private 5G, processes data right at the source—on the factory floor or at a remote site—cutting down delays and reducing reliance on distant cloud servers. Other options, like Wi-Fi or older cellular networks, often fall short in terms of coverage, security, or scalability in these rugged environments. Plus, the ability to keep sensitive data on-site is a huge draw for companies worried about privacy and compliance.

Can you share some insights into the types of industries that are embracing private 5G for digital transformation?

Absolutely. We’re seeing adoption across a wide range of sectors, particularly in manufacturing, energy, logistics, mining, and transportation. These industries often operate in challenging environments where reliable connectivity is critical. For instance, manufacturing plants use private 5G for automation and real-time monitoring, while mining operations rely on it for remote equipment control in hard-to-reach areas. Energy and logistics firms are leveraging it for tracking and optimizing operations across vast geographies. It’s really about any sector that needs robust, tailored connectivity to drive efficiency and safety.

How impressive is it that so many companies see a return on investment within just a year of deploying private 5G?

It’s incredibly significant. An 87% ROI within 12 months shows that private 5G isn’t just a shiny new tech—it’s delivering tangible value fast. Industrial operations often involve high upfront costs, so seeing returns that quickly means the technology is solving real pain points, like downtime or inefficiencies, almost immediately. It also signals that the deployment process is becoming more streamlined, making it easier for companies to justify the investment to stakeholders. This kind of rapid payback is rare in large-scale tech rollouts and underscores why private 5G is gaining so much traction.

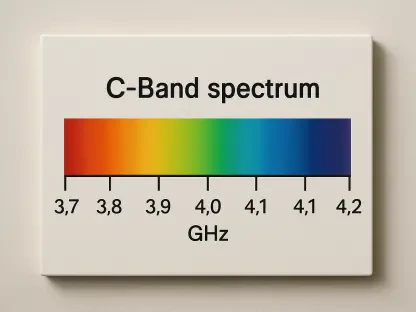

What factors make the initial setup of private 5G more cost-effective compared to other connectivity options?

One big reason is the tailored nature of private 5G deployments. Unlike broader solutions that might require overbuilding or retrofitting, private 5G can be designed precisely for a facility’s needs, avoiding unnecessary expenses. Additionally, it often integrates with existing infrastructure more seamlessly than alternatives, reducing installation headaches. The ability to use unlicensed or shared spectrum in some regions also cuts licensing costs. And frankly, the long-term scalability means companies aren’t constantly patching up outdated systems—they’re building for the future from day one, which saves money upfront.

How does private 5G help reduce ongoing operational costs for industrial firms?

Ongoing cost savings come from several angles. First, private 5G enables automation and predictive maintenance, which drastically cuts downtime and repair expenses—equipment issues are caught before they become costly failures. Second, it reduces the need for extensive wired infrastructure, lowering maintenance and energy costs. You also see savings in labor through connected worker tools that boost productivity and reduce errors. Finally, the energy efficiency of modern 5G equipment, combined with optimized operations, trims utility bills over time. It’s a cumulative effect that adds up to significant reductions.

How does the integration of private 5G with edge computing enhance the use of AI in industrial environments?

The combo of private 5G and edge computing is a powerhouse for AI because it tackles two critical needs: speed and data quality. Private 5G provides low-latency, high-bandwidth connectivity, ensuring data from sensors or machines flows instantly to edge servers. Edge computing then processes that data locally, right where it’s generated, so AI applications like real-time monitoring or predictive analytics can act without the delay of sending info to a distant cloud. This setup is perfect for dynamic industrial spaces where split-second decisions—like shutting down a malfunctioning machine—can prevent disasters.

Can you provide some practical examples of AI applications being powered by private 5G in industrial settings?

Sure, there are some fascinating use cases out there. One is predictive maintenance, where AI analyzes data from machinery sensors in real time to predict when a part might fail, allowing repairs before a breakdown. Another is digital twins—virtual replicas of physical assets—that use AI to simulate and optimize operations, like tweaking a production line for efficiency. You also see AI-driven monitoring in logistics, where cameras and sensors track inventory or vehicle movements with pinpoint accuracy. These applications all rely on the seamless, secure data flow that private 5G enables.

Why is access to real-time, high-quality data so vital for AI in industrial contexts, and how does private 5G play a role in that?

Real-time, high-quality data is the lifeblood of AI in industrial settings because decisions often need to happen instantly—think safety alerts or equipment adjustments. If the data is delayed or incomplete, AI can’t deliver accurate insights, and that could mean costly downtime or even accidents. Private 5G supports this by offering reliable, low-latency connectivity across sprawling or harsh environments, ensuring sensors and devices feed pristine data continuously. It also handles massive data volumes from pervasive sensor networks, something older technologies struggle with, making AI truly actionable.

In what ways does private 5G contribute to better worker safety in industrial operations?

Worker safety gets a huge boost from private 5G through tools like geofencing, which can restrict access to hazardous zones by sending alerts if someone enters a restricted area. Real-time monitoring systems, powered by 5G’s low latency, can detect unsafe conditions—like gas leaks or equipment malfunctions—and trigger instant alarms. Connected worker tools, such as wearables, track employee locations and vital signs, ensuring quick response in emergencies. These features create a safer environment by proactively addressing risks before they escalate into incidents.

How are connected worker tools, supported by private 5G, helping to prevent workplace accidents?

Connected worker tools are transforming safety by keeping tabs on employees in real time. For example, wearable devices can monitor fatigue levels or detect falls, instantly notifying supervisors if something’s wrong. AI-assisted monitoring, running on private 5G, can analyze video feeds to spot unsafe behaviors—like someone not wearing protective gear—and send warnings. Automated alarms tied to machinery can halt operations if a worker gets too close to a danger zone. These tools act as an extra set of eyes, cutting down on human error and reducing accident rates significantly.

What specific security advantages does private 5G offer that make it a preferred choice for industrial cybersecurity?

Private 5G shines in cybersecurity because it’s a closed, controlled network. Unlike public networks, where data might travel through shared infrastructure, private 5G keeps everything on-site, minimizing exposure to external threats. It also supports advanced encryption and authentication protocols tailored to the company’s needs. Plus, with edge computing, sensitive data doesn’t need to leave the facility, reducing the risk of interception. For industries handling critical or proprietary information, this level of isolation and customization is a massive advantage over other connectivity options.

How does private 5G technology help industrial companies reduce their carbon emissions?

Private 5G contributes to sustainability in a few key ways. It enables predictive maintenance, so equipment runs more efficiently and uses less energy. Connected devices and drones, supported by 5G, cut down on fuel-heavy travel for inspections or monitoring—think fewer truck trips across a large site. Real-time emissions tracking, powered by pervasive sensors, helps companies identify and address inefficiencies faster. Overall, by optimizing operations and reducing waste, private 5G helps firms shrink their environmental footprint, often by significant margins.

What’s your forecast for the future of private 5G in industrial applications over the next decade?

I’m incredibly optimistic about private 5G’s trajectory. Over the next decade, I expect adoption to skyrocket as costs continue to drop and more industries recognize the value of tailored connectivity. We’ll likely see even tighter integration with AI and IoT, enabling fully autonomous factories and supply chains. Security will remain a key driver, especially as cyber threats grow more sophisticated. I also foresee advancements in spectrum sharing and network slicing making private 5G accessible to smaller players. Ultimately, it’ll be the backbone of Industry 4.0, powering smarter, safer, and more sustainable operations across the globe.