The Industrial Internet of Things (IoT) is fundamentally transforming the landscape of global industries by seamlessly connecting devices, sensors, and software to elevate efficiency, productivity, and real-time decision-making capabilities. From the bustling floors of manufacturing plants to the intricate networks of energy grids, transportation systems, and healthcare facilities, this technology is igniting a revolution through automation and predictive maintenance. A recent comprehensive report forecasts the trajectory of this market from the current year through 2035, predicting unprecedented growth and profound transformation across sectors. This analysis delves into the critical insights, dynamic market forces, and forward-looking perspectives that define this rapidly evolving domain, shedding light on how industries worldwide are poised to adapt and thrive in an increasingly connected future.

Market Growth Drivers and Opportunities

Technological Advancements Fueling Expansion

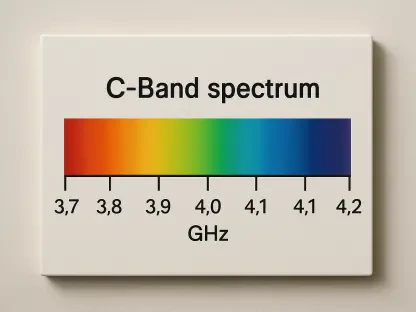

The surge in the Industrial IoT market is largely propelled by the widespread adoption of connected devices, cutting-edge cloud computing solutions, and a relentless drive toward digital transformation across diverse industries. These technologies are not merely tools but catalysts that enable companies to streamline operations, drastically reduce downtime, and make informed decisions through sophisticated data analytics. The momentum is particularly evident in sectors like manufacturing, where IoT systems monitor equipment health in real time, preventing costly failures before they occur. Beyond operational benefits, the push for digitalization aligns with broader industry goals of agility and competitiveness, positioning Industrial IoT as a cornerstone of modern business strategy. As more organizations recognize these advantages, the market is set to expand rapidly over the coming decade, fueled by an insatiable demand for efficiency.

Emerging applications such as smart manufacturing and predictive maintenance stand out as pivotal growth opportunities within the Industrial IoT landscape. Smart manufacturing leverages IoT to create interconnected factories where machines communicate seamlessly, optimizing production lines and minimizing waste. Predictive maintenance, on the other hand, uses sensor data to anticipate equipment issues, allowing for timely interventions that save both time and resources. These applications are transforming traditional industrial models into dynamic, responsive systems capable of adapting to changing demands. Moreover, the scalability of IoT solutions means that even niche sectors can benefit from tailored implementations, opening doors to innovation in areas previously untouched by digital tools. This wave of opportunity underscores the transformative potential of IoT as industries race to harness its full capabilities.

Integration with Cutting-Edge Tech

The convergence of Industrial IoT with advanced technologies like artificial intelligence (AI), machine learning (ML), and blockchain is redefining the boundaries of industrial capability and security. AI and ML algorithms analyze vast streams of data generated by IoT devices, uncovering patterns and insights that drive smarter operational decisions and enhance automation. Blockchain, meanwhile, introduces a layer of security by ensuring data integrity and transparency across distributed networks, addressing critical concerns in industries handling sensitive information. This synergy not only boosts the functionality of IoT systems but also builds trust in their reliability, encouraging broader adoption. As these technologies mature, their integration is expected to unlock new levels of efficiency and innovation, reshaping industrial processes in profound ways.

A notable shift toward subscription-based and as-a-service models is making Industrial IoT solutions more accessible to businesses of varying sizes, from sprawling enterprises to small startups. These flexible models lower the barrier to entry by reducing upfront costs, allowing companies to pay for only what they use while scaling as needed. This democratization of technology enables smaller players, often constrained by budget limitations, to compete on a more level playing field with industry giants. Additionally, service-based approaches often come with built-in updates and support, ensuring that systems remain current without requiring significant internal expertise. This trend is poised to accelerate market growth by expanding the user base, fostering a more inclusive industrial ecosystem where innovation can flourish across all scales of operation.

Challenges and Barriers to Adoption

Cybersecurity and Cost Concerns

One of the most pressing challenges facing the Industrial IoT market is the persistent threat of cybersecurity risks, which loom large as more devices become interconnected across industrial networks. With every connected sensor or machine, the potential attack surface expands, making systems vulnerable to breaches that can disrupt operations or compromise sensitive data. Industries such as energy and healthcare, where downtime or data leaks can have catastrophic consequences, are particularly at risk. Addressing these threats requires robust security protocols and constant vigilance, yet many organizations struggle to keep pace with evolving cyber dangers. As the market grows, the urgency to develop and implement comprehensive safeguards becomes paramount to sustaining trust and ensuring operational continuity.

High upfront costs represent another significant barrier to the widespread adoption of Industrial IoT, often deterring organizations from making the leap despite the long-term benefits. The expenses associated with hardware, software, and system integration can be prohibitive, especially for smaller enterprises with limited capital. Beyond initial investments, ongoing maintenance and updates add to the financial burden, creating hesitation among potential adopters. Compounding this issue is the shortage of skilled personnel capable of managing and scaling IoT systems effectively. Without trained professionals to oversee implementation and operation, companies risk underutilizing their investments or encountering costly errors. Tackling these cost and talent challenges is essential for unlocking the full potential of IoT across diverse industrial landscapes.

Integration with Legacy Systems

Integrating Industrial IoT with outdated infrastructure poses a formidable challenge, particularly for small and medium-sized enterprises (SMEs) that often rely on legacy systems built decades ago. These older setups were not designed to accommodate the connectivity and data demands of modern IoT solutions, leading to compatibility issues that can stall deployment. Retrofitting or replacing such systems requires significant investment and technical expertise, resources that many SMEs lack. The result is a fragmented adoption rate, where larger corporations with deeper pockets advance rapidly while smaller players lag behind. Bridging this gap demands innovative approaches to integration that minimize disruption while maximizing the value of existing assets, ensuring that progress is inclusive across the industrial spectrum.

Standardization and interoperability remain critical hurdles in blending Industrial IoT with diverse systems, as the lack of uniform protocols can lead to inefficiencies and communication breakdowns. Without agreed-upon standards, devices and software from different vendors may fail to work cohesively, creating operational silos that undermine the promise of a connected ecosystem. This issue is especially pronounced in industries with complex supply chains, where multiple stakeholders must collaborate seamlessly. Efforts to establish industry-wide benchmarks are underway, but progress is slow, often hampered by competing interests and technological disparities. Until interoperability becomes the norm, the full benefits of Industrial IoT—such as streamlined processes and real-time data sharing—will remain out of reach for many, highlighting the need for concerted action among industry leaders and policymakers.

Regional Dynamics and Growth Patterns

Established Markets: North America and Europe

North America and Europe stand as the vanguard of the Industrial IoT market, underpinned by advanced technological ecosystems, substantial research and development investments, and progressive regulatory frameworks. In North America, particularly the U.S., a culture of innovation drives rapid adoption, with industries leveraging IoT to maintain a competitive edge in global markets. Strong infrastructure supports seamless deployment, while government policies often incentivize digital transformation through grants and tax breaks. This region’s leadership is further bolstered by a high concentration of major tech firms that continuously push the boundaries of IoT applications. As a result, North America remains a benchmark for how industrial connectivity can reshape operational paradigms, setting a high standard for others to follow.

Europe, while sharing similar strengths, carves a unique path with its emphasis on sustainability and smart factory initiatives as key drivers of Industrial IoT growth. The region’s commitment to green technologies aligns closely with IoT solutions that optimize energy use and reduce waste, particularly in manufacturing hubs like Germany. Regulatory support, such as stringent data protection laws, ensures that IoT deployments prioritize security and privacy, fostering public trust. Additionally, collaborative efforts across European nations facilitate cross-border innovation, creating a cohesive market environment. This focus on sustainable and interconnected industrial systems positions Europe not just as a leader in adoption but as a pioneer in aligning IoT with broader societal goals, offering valuable lessons for global markets.

High-Growth Regions: Asia-Pacific and Beyond

Asia-Pacific emerges as the fastest-growing region for Industrial IoT, propelled by rapid industrialization, expansive manufacturing bases, and robust government backing in countries like China and India. The sheer scale of production in this region creates an ideal environment for IoT solutions that enhance efficiency and reduce costs, particularly in densely populated industrial zones. Governments are actively investing in digital infrastructure, with policies designed to accelerate IoT adoption as part of broader economic development plans. This momentum is transforming Asia-Pacific into a global powerhouse for industrial innovation, where the pace of change often outstrips that of more established markets. The region’s trajectory suggests it will play a central role in shaping the future of connected industries worldwide.

Emerging markets in Latin America and the Middle East & Africa hold significant potential for Industrial IoT growth, though they grapple with infrastructural and financial constraints that temper progress. In Latin America, countries with growing industrial sectors are beginning to explore IoT to boost competitiveness, but limited access to capital and uneven technological readiness pose challenges. Similarly, the Middle East & Africa region offers untapped opportunities, particularly in energy and resource management, yet faces hurdles like insufficient connectivity and funding gaps. Foreign investments are gradually helping to bridge these divides, bringing modern solutions to areas previously out of reach. While these regions may not yet match the maturity of North America or the speed of Asia-Pacific, their latent potential signals a future where global IoT adoption becomes truly inclusive, provided barriers are systematically addressed.

Future Horizons for Industrial IoT

Path to Industry 4.0 Dominance

Reflecting on the insights gathered, it becomes evident that Industrial IoT has already established itself as a linchpin of industrial evolution by paving the way for Industry 4.0 through relentless automation and connectivity. The strides made in integrating real-time data analytics have reshaped how industries approach decision-making, turning reactive processes into proactive strategies. Over the past years, the groundwork laid by pioneering companies and supportive policies in key regions has demonstrated the scalability of IoT solutions across varied applications. This historical momentum underscores the technology’s role as a transformative force, with each advancement building toward a more interconnected industrial future. The journey thus far highlights both the achievements and the persistent need for innovation to sustain growth.

Strategies for Overcoming Barriers

Looking ahead, stakeholders must prioritize actionable strategies to navigate the challenges that have hindered Industrial IoT adoption, focusing on cybersecurity enhancements and cost-effective deployment models. Collaborative efforts between industry leaders and governments should aim to establish universal standards, ensuring interoperability while investing in training programs to address the skills gap. Incentives for SMEs, such as subsidized access to subscription-based IoT services, could level the playing field, fostering broader participation. Additionally, leveraging emerging technologies like AI and blockchain to bolster security will be crucial in maintaining trust as systems scale. By addressing these areas with targeted solutions, the industrial sector can build on past lessons to create a resilient, inclusive IoT ecosystem that drives progress through 2035 and beyond.